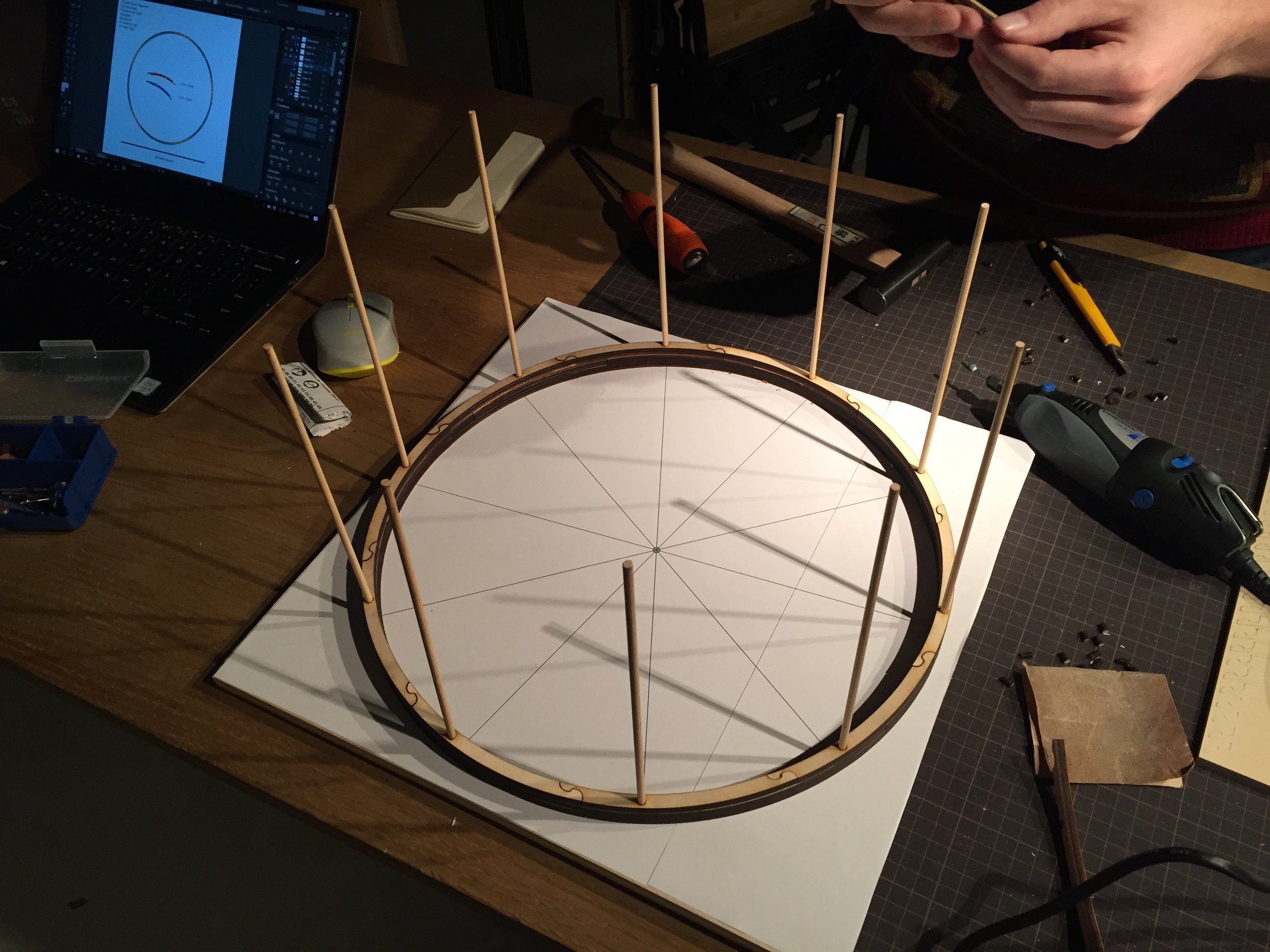

I'm starting a new two-part project involving digital fabrication and drums. The first challenge is to design and build fully laser cutter-able drum shells. The first prototype isn't finished yet but it's already looking pretty cool so I had to post a few pictures of the process of putting it together.

The 340 pieces that will eventually make up this 14 inch snare drum were cut from 6mm plywood on a laser cutter. Each layer of wood is staggered so that the joints where the pieces lock don't form a weak point on the shell. I designed the drum in Illustrator to be assembled without having to use glue, the idea being that, with the interlocking pieces, the 4mm dowels, and the pressure of the hoops when they go on, everything will hold together. We'll see if that turns out to be true or not, but at this point it's already feeling pretty solid.

For the hoops, lugs, and hardware I'll be recycling some parts from a rusty old snare drum my friend bought for ¥360 (a few bucks). Part of the idea behind this was to come up with a super cheap way to DIY make a drum, and at this point I'd estimate the total cost is going to be around $30.